The Story of a Miner from Northern Ontario

I had the pleasure to interview a hard-working miner from Sudbury, Ontario, Ryley is a 21-year-old Canadian who actively works in Sudbury and Timmins with Vale S.A. Here are the

Mining has been an integral part of human civilization for centuries, providing us with essential resources like coal, metals, and minerals. While surface mining is commonly known, there exists a lesser known but equally important method known as underground mining. In this blog, we’ll explore the fascinating world of underground mining techniques, specifically focusing on room and pillar, longwall, and cut-and-fill methods. For those unfamiliar with underground mining, let’s begin with a brief overview.

Underground mining involves the extraction of valuable minerals and ores that lie deep below the earth’s surface. Unlike surface mining, which removes materials from the top layers, underground mining accesses mineral deposits through shafts or tunnels. These mining techniques are essential when deposits are too deep or geologically unsuitable for surface excavation.

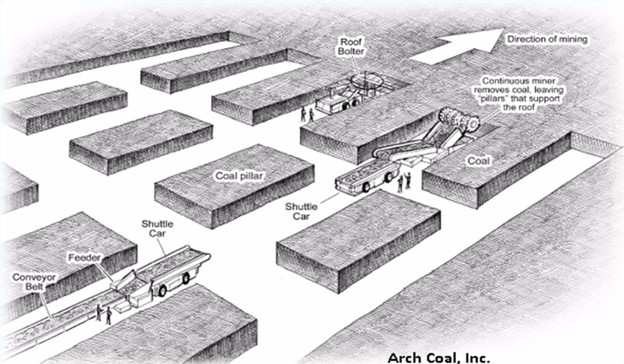

The room and pillar method is one of the oldest and simplest forms of underground mining. Here’s how it works:

Application: This technique is commonly used to extract coal, salt, and other sedimentary deposits. It is particularly useful when the ore body is relatively horizontal, and the surrounding rock is stable.

Process: The ore is mined by creating a series of interconnected tunnels or “rooms.” These rooms are then supported by leaving intact pillars of ore or rock between them, hence the name “room and pillar.”

Safety: This method provides stable support for the mine, minimizing the risk of collapse.

Selective Mining: Operators can choose specific areas for extraction, leaving other portions untouched.

Resource Recovery: While it ensures safety, room and pillar mining may not extract all the available resources, leaving some behind in the pillars.

Land Subsidence: Over time, the extraction of material may cause surface subsidence, leading to ground settling and potential surface damage.

Longwall mining is a highly efficient underground mining technique that maximizes resource recovery.

Here’s how it works:

Application: It is primarily used for coal mining, especially when the coal seam is relatively thick and continuous.

Process: In this method, a cutting machine called a shearer moves back and forth along the coal seam, cutting the coal while hydraulic supports hold the roof in place. As the shearer advances, the hydraulic supports are extended, allowing the roof to collapse behind the mining face.

High Resource Recovery: Longwall mining extracts a significant portion of the coal seam, leaving minimal coal behind.

Efficiency: This method enables continuous mining operations, leading to higher production rates.

Ground Subsidence: Similar to room and pillar, longwall mining can cause subsidence, which may affect surface structures.

Technical Complexity: Longwall mining requires advanced machinery and experienced operators, making it more expensive to set up and maintain.

Application: This method is commonly employed in metal ore mining, where the ore body is narrow or steeply inclined.

Process: In cut-and-fill mining, horizontal access tunnels are created along the ore body’s length. The ore is extracted in horizontal slices, and the void left behind is filled with waste rock or other materials.

High Selectivity: Cut-and-fill mining allows for selective extraction of valuable ores, reducing waste.

Supportive: Filling the mined-out areas provides excellent ground support, minimizing the risk of ground collapse.

Time-Consuming: The cut-and-fill method can be slower compared to other techniques due to the sequential extraction process.

Expensive: The need for filling materials can add to the overall mining costs.

Underground mining techniques, such as room and pillar, longwall, and cut-and-fill, play a crucial role in extracting valuable resources hidden deep within the Earth. Each method comes with its unique applications, advantages, and challenges. Room and pillar mining offer safety and selectivity, longwall mining boasts high resource recovery rates, and cut-and-fill mining allows for the selective extraction of valuable ores.

As we continue to rely on these vital resources, it’s essential to strike a balance between mining efficiency, environmental considerations, and sustainability. Understanding the complexities of underground mining helps us appreciate the immense effort that goes into providing us with the materials that power our modern world.

Sign up for updates about our work at YCR. Please sign up using a personal email and not a work or school email if possible.

"*" indicates required fields

I had the pleasure to interview a hard-working miner from Sudbury, Ontario, Ryley is a 21-year-old Canadian who actively works in Sudbury and Timmins with Vale S.A. Here are the

From an early age, I wanted to know how things worked. I remember always disassembling toys and gadgets, then trying to reassemble them back to their original states.

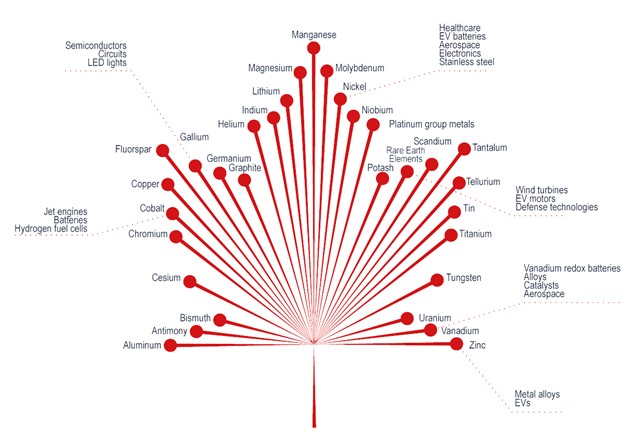

Whether it’s because of unsustainable and inhumane cobalt mining in the Congo, China’s dominance over global supply chains of rare earth elements, or the mass lithium shortages that are projected