Mozzam Ali Khowaja – October 3, 2022

About The Author:

Hydrogen’s Place in Canada’s Future

The Story of Hydrogen (So Far)

As it sits atop the periodic table, hydrogen is the most abundant element in the universe. It accounts for approximately 75% of matter in the universe, as it makes up the sun, water, and hydrocarbons. However, on earth, it is rarely found in elemental form as it tends to adhere to other elements (in the case of water, it compounds with oxygen) because of its high reactivity and lightweight. Hence, it must be extracted from compounds to be transformed into a useful format by energy-intensive methods.

Pledges made by significant state leaders (United States – $11.4B, United Kingdom –£11.6B, European Commission €28B, Japan – $14.8B, France – €6B) during COP26, whose countries constitute greater than 70% of global GDP and greenhouse gas emissions, have mainstreamed the transition to carbon neutrality. Moreover, recent political tensions have further accentuated the energy security concerns for countries across the globe, hence stimulating the exploration of energy resources alternative to fossil fuels.

The transition to renewables, which involves utilizing hydrogen as an energy resource, might appear modern, but the history of hydrogen energy dates to 1806 when it was used to power the first internal combustion engine. Hydrogen is often considered a viable alternative to hydrocarbons as it is light, energy-dense (120 MJ/kg for hydrogen against 45.5 MJ/kg for diesel and 45.8 MJ/kg for gasoline), and environmentally friendly as it does not generate direct emissions of any pollutants or carbon dioxide.

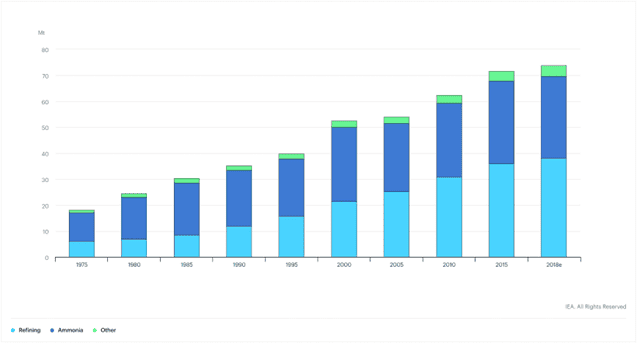

Moreover, as hydrogen is a versatile element with a plethora of functions which include: oil refining, fertilizer manufacturing (for ammonia production), methanol production, metal treatment, and production industries, economies of scale can be applied for more affordable, efficient, and green production.

Figure 1 shows the growth in global demand for hydrogen.

Figure 1: The global demand for hydrogen and its corresponding purpose (International Energy Agency, 2019)

Hydrogen can be produced from fossil fuels and biomass by thermochemical processes, from water by electrolysis, or a mix of both. Currently, fossil fuels, especially natural gas, are predominant production sources of hydrogen production. In 2018, fossil fuels accounted for more than 99% of hydrogen production.

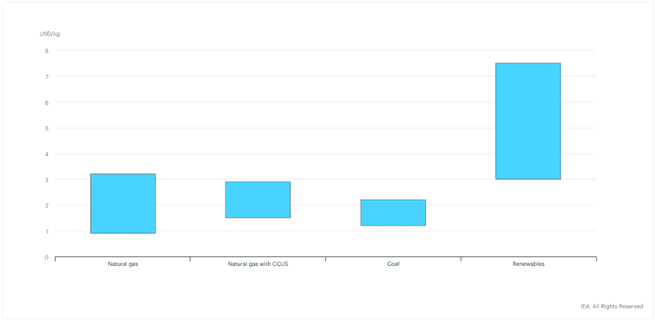

This overwhelming reliance on fossil fuels for hydrogen production contributes to roughly 830 million tonnes of carbon dioxide annually. However, because cost is a major factor driving the selection for the production process to be employed, industries tend to choose the source with the lowest price, regardless of its carbon footprint. Figure 2 illustrates the cost of hydrogen production from multiple sources.

Figure 2: Hydrogen production costs by production source (International Energy Agency, 2019)

Hydrogen ‘Colours’

Hydrogen has been labeled with various colors based on its production source/type. The breakdown and analysis of the hydrogen color code are as follows:

Grey hydrogen relies on the steam methane reformation (SMR) process, where methane reacts with steam at elevated temperatures to produce hydrogen and carbon monoxide. Subsequently, steam reacts with carbon monoxide to produce additional hydrogen and carbon dioxide. More than 95% of the global hydrogen is manufactured using SMR. Under grey hydrogen, greenhouse gases are not sequestered.

Blue hydrogen is manufactured using natural gas, and all carbon dioxide emissions generated in this process are permanently contained underground by adopting Carbon Capture, Utilization, and Storage (CCUS) technology. Steam-methane reformation (SMR) is a conventional way of producing blue hydrogen. But more recently, autothermal reforming (ATR), which also uses methane as its feed, has been employed for production as the carbon capture rate for this method surpasses that of SMR at a cheaper cost.

Green hydrogen is produced from renewable energy sources such as wind, solar, or hydropower, by the process of electrolysis. As the products of electrolysis are only hydrogen and water, no greenhouse gases are produced. However, green hydrogen requires an excess renewable power supply. Moreover, the energy from renewable resources must be perpetual throughout the day to allow consistent hydrogen production. Hence, as the renewable power supply is already competitive, and there is significant intermittency associated with renewable resources (due to natural factors), the production of green hydrogen is not feasible.

Turquoise hydrogen employs the pyrolysis of methane to produce hydrogen. Solid carbon is a by-product of the reaction, so it does not require sequestration. The reaction is endothermic (requires heat); therefore, the emissions generated depend on the thermal energy source adopted in the production process. Turquoise hydrogen production can become carbon neutral if renewable energy resources power the process.

Pink hydrogen uses nuclear energy to power the electrolysis process. However, the bulk of nuclear energy is being harnessed to produce low-carbon electricity for domestic and industrial consumption. Hence, only surpluses of nuclear electricity can be allocated to pink hydrogen. Furthermore, the addition of nuclear facilities to existing energy infrastructure is not feasible as these require substantial capital investments, pose safety concerns, and the cost for lifetime extensions is high when compared with other clean energy alternatives.

Why Does Blue Hydrogen Stand Out?

Blue hydrogen has received extraordinary attention and investment as an energy carrier in Canada, especially in Alberta. Canada’s Hydrogen Strategy and Alberta’s Hydrogen Roadmap aim for a hydrogen economy that utilizes CCUS to cater to domestic heating, industrial, transportation, power generation, and export markets. In addition, major oil and gas companies (Shell, Suncor, ATCO, and Enbridge), that are among the largest consumers and producers of hydrogen, plan to build infrastructure to produce blue hydrogen as part of their decarbonization strategies in the latter half of this decade. Therefore, as governments and industries promote their blue hydrogen-based carbon neutral approach, it is crucial to deconstruct its climate potential and carbon intensity.

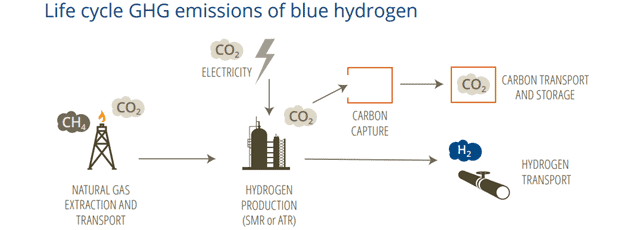

To precisely assess the carbon footprint of blue hydrogen, the entire cycle of production must be examined. Figure 3 illustrates blue hydrogens’ production phases and the accompanying GHG emissions.

Figure 3: Blue hydrogen production process (Pembina Institute, 2021)

The total emissions of blue hydrogen can be attributed to two primary functions:

- Upstream carbon emissions associated with the extraction and transport of natural gas.

- Emissions associated with the production and transport of hydrogen and the delivery of captured carbon to storage facilities

The upstream emissions are contingent on the quality of the methane handling and processing infrastructure, and the proportion of renewable energy sources used to power the processing and transport of methane. Degenerating infrastructure can cause methane to escape into the surroundings. Strict government regulations that mandate monitoring such emissions and set performance standards for equipment can curb these venting methane emissions. Moreover, electricity generation from non-emitting sources is key to eliminating these upstream emissions.

The efficiency of the carbon capture system utilized in the hydrogen production process is a crucial indicator of the carbon intensity of the process. Technologies that yield 90% or higher capture rates are vital to reducing carbon emissions. The Shell-operated Quest facility in Alberta has an estimated capture rate of 43%. In comparison, Air Products Canada has set an objective of a 95% capture rate for its proposed facility and plans to utilize ATR to achieve this target. In addition, either carbon-neutral freight transport or an efficient pipeline network with minor fugitive emissions is required to transport the feed (methane) and the product (hydrogen).

Conclusion

If governments streamline the carbon-neutral hydrogen expansion, it can become a viable alternative to fossil fuels. In the short term, current infrastructure such as pipeline networks could be upgraded and leveraged to transport hydrogen. Industrial ports, such as the Gulf coast which is capable of refining 47% petroleum and processing 51% natural gas for the United States, must be established as epicenters for clean hydrogen production as these could accommodate the significant consumers of hydrogen. Moreover, the surplus hydrogen supply at these ports would accelerate accessibility and encourage the long-haul freight transport industry to transition to an alternative fuel.

Policies that incentivize fuel cell electric vehicles (FCEVs) for domestic consumers and short-haul transportation reduce the risks for investors and guarantee profits that can be invested in researching and developing low-cost clean technologies. The formation of international marine routes for trade expands the market and provides resources to customers that lack the resources to produce clean hydrogen. The engagement and coordination achieved through these measures will encourage stakeholders along the hydrogen value chain to utilize hydrogen created from low or non-emitting sources, as scaling the usage will lower production costs.